DATE: 04-05-25 TIME: 12:00 – 5:00 ~ 5:00

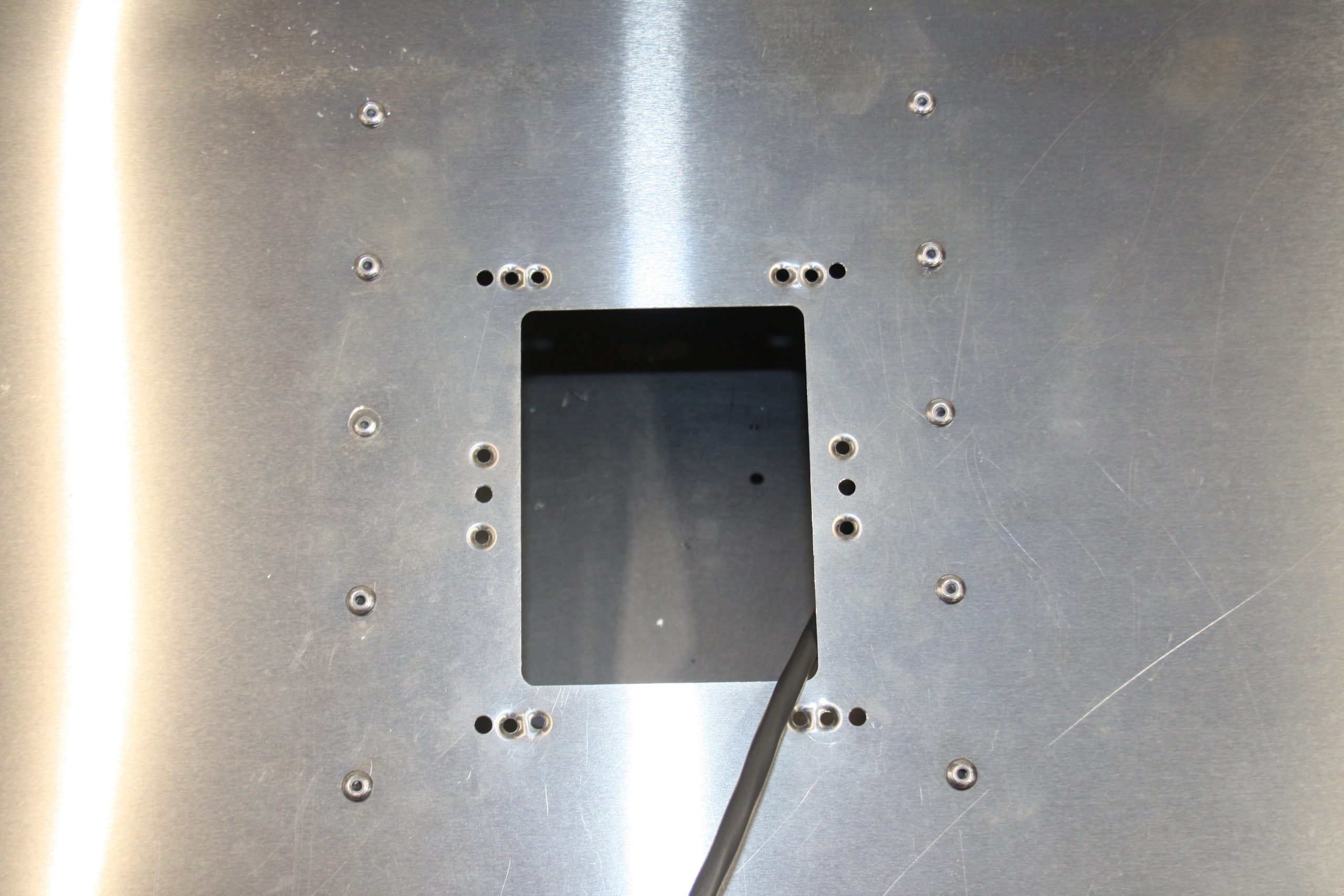

I started working on the trim tab cover plate modifications as soon as I came into the workshop and, unfortunately, forgot to activate the cameras. They were on, but not active for recording so most of the completion of attaching the nutplates to the skin is missing although I did take a few snapshots with a Canon so you can see how they look.

In addition to purchasing the nutplates (K1000-06 and K2000-06), machine screws (AN526), elastic lock nuts (AN365) and washers (AN960-6) for attaching the servo to the upper skin and the cover plate to the lower skin, I also purchased a 6 pin connector and pins so that, should I, or someone, need to replace the servo at any point it will just be a matter of unplugging the connector rather than having to cut and re-crimp wiring.

I used solid rivets AN426AD3-3.5 for attaching the nutplates to the elevator skin. My 3″ yoke would not fit into the cutout so I purchased a 1.5″ yoke and another set of squeezer handles which made it easier. In the process, I used a mini-clamp to hold the nut plate in place and inserted two rivets. Then I partially squeezed one rivet, removed the clamp, and finished squeezing both rivets.

I then started working on attaching the trim tab to the elevator. There are no holes in the elevator skin for attaching the hinge so you have to do this yourself. The holes in the hinge, 18 of them, are drilled for A3 rivets and the instructions in the IPL don’t address attaching the hinge to the elevator at all, while the drawing calls for A4 rivets.

The key issue here is to make sure that the hinge will not rub on the elevator skin and will move freely. The easiest way to do this, for me, was to hold the trim tab, I had already attached the hinge to the trim tab, flush up against the trailing edge of the elevator and, using the hinge as a ruler, draw a line parallel to the trailing edge. Then I measured 2mm from that line towards the elevator trailing edge and drew another parallel line. Now, lining up the hinge so that the second line appears in the centre of the holes in the hinge one can match drill through the hinge into the elevator skin and be certain that the tab will move freely.

As of this moment, I have not drilled the holes as I am waiting for a response from Roger with respect to whether it is OK to use A3 rivets to attach the hinge or if I must use A4s, having to drill the hinge holes larger.