DATE: 09-27-2024 TIME: 4:30

I was away this past weekend at the Zenith Aircraft Open Hangar Days in Mexico, Missouri and then visiting in Texas so nothing got done for a few days.

I started the day by attaching my newly made HS-1008 left and right brackets to the HS-1002 and then final drilling the #30 holes common to the 1002 spar and 1007 spar doubler.

I then moved the spar out of the way and brought the 2 HS-1001 skins down on to the bench to remove the inside vinyl in preparation for attaching the HS-905 nose ribs. During this process my apprentices EJ and his grandson Ty showed up to help complete the vinyl removal.

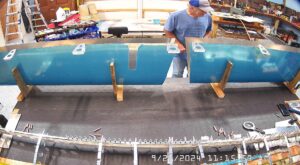

We then set the fabricated cradles we had made with the boards on the bench and I placed one of the skins into two of the cradles and promptly cracked one of the cradles so I took the opportunity to clean up the cradles to make them smoother and more evenly distribute the stress on the skin. Next time I have to make cradles I’ll buy ply.

We then had no problems attaching the HS-905 ribs into the nose of each of the stabilizer skins, and the the HS-1002 front spar with the HS-1004 and HS-904 ribs attached. That’s when we discovered we did not have enough 3/32 clecos (zinc / silver). I think I had approximately 200 or 225. So I counted the holes in the skins and there are more than 350, which is the number of silver clecos recommended in the Vans RV-10 manual. So I ordered 200 more from SkyGeek.com, which is where, incidentally, I bought my SW P60-G2 wash primer and catalyst. While I am on this subject, I bought a 5 gallon can of R7 K 44 catalyst reducer off eBay at a price well below the 1 Gallon per container price. Given that the 2:1 (reducer:primer) ratio works better than the recommended 1.5:1 given the thickness we’re looking for, I figure I’ll probably have no problem using 6 gallons of reducer.