DATE: 12-03-2024 TIME: 11:24 – 5:17 ~ 6:15

I was away over the thanksgiving week so did not get anything done during that week except to read ahead in the Vans RV-10 Empennage assembly manual. Mostly I left reading ahead until either the night before or the morning off a work session but as I figured there was nothing to lose doing some review and preview.

I started my morning working on finishing the assembly of the F-1037 B & C bellcrank rib angles and nutplates and then riveting the bellcrank angles to the F-1029 left and right ribs. Nothing terribly complicate here, just make sure you have the correct nutplates in the correct positions as the 2 forward nutplates on each rib angle are different to the aft 4 as they are related to holding the battery holder. All the rivets are countersunk.

After finishing that I moved the camera that was focused on the vice to focus on the tailcone proper as that is where I was going to be spending most of my time. This way I have reasonably closeup views from all quadrant on the primary assembly location and I was pretty much finished with the vice at this point.

The vast majority of the day was spent riveting the Vans RV-10 tailcone skins to the frames and bulkheads. I did put some rivets in on my own before EJ showed up but figured it wasn’t worth the risk and he arrived right after lunch anyway. So, back to page 10-20 and riveting the F-1073 skins to the frame and bulkheads. Despite reading and re-reading the rivets, I missed the fact that the rivets that are used at the intersection of the frames / bulkheads and F-1073 skins and F-1047 stiffeners, AN426AD3-4, are longer, than the ones used for just the skin to frame / bulkhead or skin to stiffener, AN426AD3-3.5. So I accidentally used 3.5 length rivets in those holes and, despite initially deciding to leave the rivets, ended up drilling them out and replacing them with the correct length. It’s a strength issue and I don’t want to lose rivets in flight !

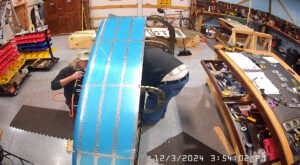

We had established a process of putting a string of rivets in place and holding them there with rivet tape. I guess we could have used scotch tape but as I had two rolls of rivet tape we used that, and re-used each piece a number of times. This made it much quicker than placing each rivet and setting them individually, although that may have helped to avoid using the incorrect rivets occasionally. After this, I decided I would triple check the rivets and place any “odd” rivets before placing all of the “normal” rivets specified.

I will tell you, after a day of riveting the tailcone, my right shoulder was pretty sore.