DATE: 11-20-2024 TIME: 11:05 – 3:57 ~ 5:00

Today I first had to continue with removing vinyl from the appropriate parts in preparation for dimpling and priming as we had not finished this process yet. Step 3 on page 10-17 says to do the priming you want prior to beginning riveting.

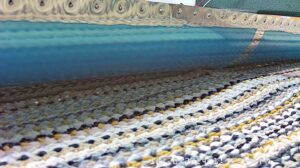

With the vinyl all removed and the deburring finished, it was time to move on to the dimpling and machine countersinking off all the tailcone skins, F-1073, 74 and 75 and the thicker parts like angle brackets, braces and longerons, F-1032.

Most of the dimpling we were able to accomplish on the large C-frame tool. It doesn’t take long but I do still intend to replace the C-frame bolt handle with a pneumatic piston and a pedal as this will make it possible to use the dimpler where the handle makes it impossible.

I recommend everyone double check before they dimple or countersink to make sure they don’t dimple of countersink holes that should be left flat.

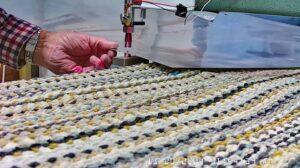

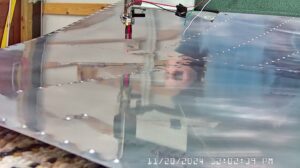

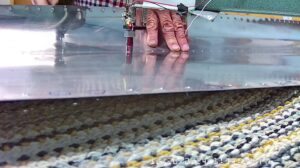

Here are a few overhead shots of working on the C-frame dimpler with the skins, stiffeners, bulkheads and frames. You can see there are two of us working the dimpling process. One person can probably manage most of it but it will take much longer and the risk of screwing up, or distorting the skin or flange is much higher.